EPS and the Environment

EPS is a smart choice to reduce our impact on the environment when used in the building, construction and packaging industries. The manufacture of EPS does not produce any harmful CFCs or HFCs. It is also able to be recycled at many stages of its life-cycle. EPS is a safe and sustainable product which complies with technical and environmental standards.

Sustainability

The lightweight nature and the strength of EPS means it is able to significantly reduce transport costs, fuel consumption, damage to products, and maintain the cold chain temperature of food, minimising environmental impacts.

Less than 0.1% of global crude oil consumption goes towards the production of EPS whilst it can deliver up to 200 times its own resource in thermal energy savings. As a result using EPS instead of other non-plastic materials saves more oil than the quantity required to manufacture it.

EPS can be recycled up to 20 times without any degradation of its physical properties.

Manufacture of EPS

No ozone-layer-depleting CFCs and HCFCs are produced in the manufacture of EPS, and there are no harmful materials present in the final product.

Steam is applied to tiny grains of styrene to produce EPS beads which are then moulded into blocks or shapes with steam to bind the beads together using very little energy.

There is no solid waste produced in the manufacture of EPS and all manufacturing waste can be completely recycled in the production process.

Find out more about the production of EPS in our Technical Information Section.

Effects on the Atmosphere

EPS insulation helps reduce CO2 emissions by inhibiting the passage of cold and heat. The use of fossil fuels for domestic and industrial heating significantly contributes to the global output of CO2. Estimates suggest that the use of EPS insulation could cut carbon dioxide emissions by up to 50%.

Within 6 months the energy used to manufacture EPS insulation is recovered in buildings where it is installed. Because of its cellular structure EPS is dimensionally stable, and will not settle over time. EPS used and installed correctly does not deteriorate with age and as such is able to deliver constant R values for the life of the building.

Recycling of EPS

EPS can be recycled at many stages of its life cycle. During production internal waste can be ground and mixed in various proportions with virgin material in the production of EPS blocks and mouldings.

Recycled EPS can be mixed with plaster to provide insulated coatings and concrete to produce light weight blocks.

When melted, EPS becomes solid polystyrene and shrinks to its original volume. Once solidified it is reground into solid granules and used in the production of simple polystyrene products such as pens, coat hangers and cassette tape.

Several EPS manufacturers operate closed loop schemes with their merchant customers and will take back clean offcuts from building sites.

Contact details for members that provide this service are available here

There are also organisations that provide collection or drop facilities for either packaging or construction EPS. Generally the EPS material is crushed to reduce its volume and exported overseas for further recycling. Some 300 tonnes per annum of EPS is diverted from landfill through this process

Companies known to Plastics New Zealand that provide this service are available here

EPS in Landfill

There is increasing concern over the environmental impact and waste disposal problems of plastics. We often hear that many of our waste problems are caused by plastics. In reality, the total amount of plastics in our landfill is only 7% by weight and EPS accounts for less than 0.1% of this.

The foam scrap of EPS improves the aeration of landfills and contributes to a faster degradation of organic substances. EPS products do not degrade into harmful substances, are not water soluble and do not give off any water soluble substances which could lead to contamination of ground water.

EPS packaging is able to extend the life of food by keeping it fresh and at the correct temperature for longer. As a result it helps reduce food spoilage, alongside the amount of domestic rubbish (around 30% by weight is wasted food) going into landfills.

Efficient use of Resources

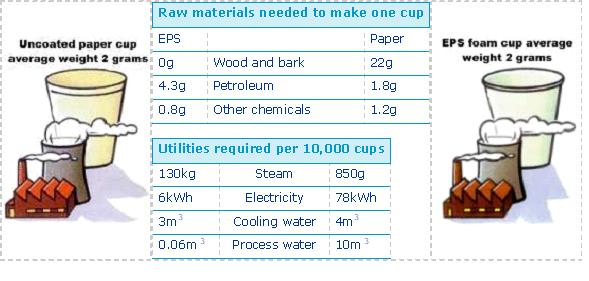

The most effective way to reliably assess the overall environmental impact of materials is by 'Life Cycle Analysis'. This internationally accepted method evaluates all impacts, including raw material processing, product manufacture, energy consumption in processing, manufacture and use, and effects on the environment of disposal and recycling. There are many examples which illustrate the benefits of using EPS.

EPS is produced from oil and as it comprises approximately 98% air, it consumes only a small fraction of one percent of oil use. On a volume basis, EPS production uses between one third and one half of the energy required for an equal volume of cardboard. Many homes, cool stores, commercial and industrial buildings use EPS for insulation to save valuable energy.

Home insulation can reduce heat losses by up to 70%. For each kilogram of oil used in the manufacture of EPS insulation, savings of up to 200 kilograms of heating fuel can be made over the average life of a house.

The World Health Organisation estimates that up to 30% of food stuff production is lost through lack of suitable storage, transport and packaging.

EPS plays a vital role in reducing this unnecessary waste by being the first choice for cool store insulation and insulated food containers - EPS food packaging allows the safe transportation of food by air and road ensuring it reaches its destination without deterioration.