Bioplastics & Degradables

The terms "biopolymer" or "bioplastic" have been applied to a wide range of plastics and have been subjected to a wide range of interpretations. These terms are also being used, incorrectly, to describe biodegradable, or compostable plastics, and this is adding to the confusion. We would like to try and clarify what this terminology means, and explain how these types of materials have come to exist.

Background

Concerns about fossil resources (oil and gas) depletion, has led to efforts to replace conventional oil and gas-based plastics with plastics made from natural and renewable resources such as wood (cellulose), vegetable oils, sugar and starch. These types of plastics can be defined as 'bio-based' plastics but are often incorrectly termed 'biopolymers' or 'bioplastics'.

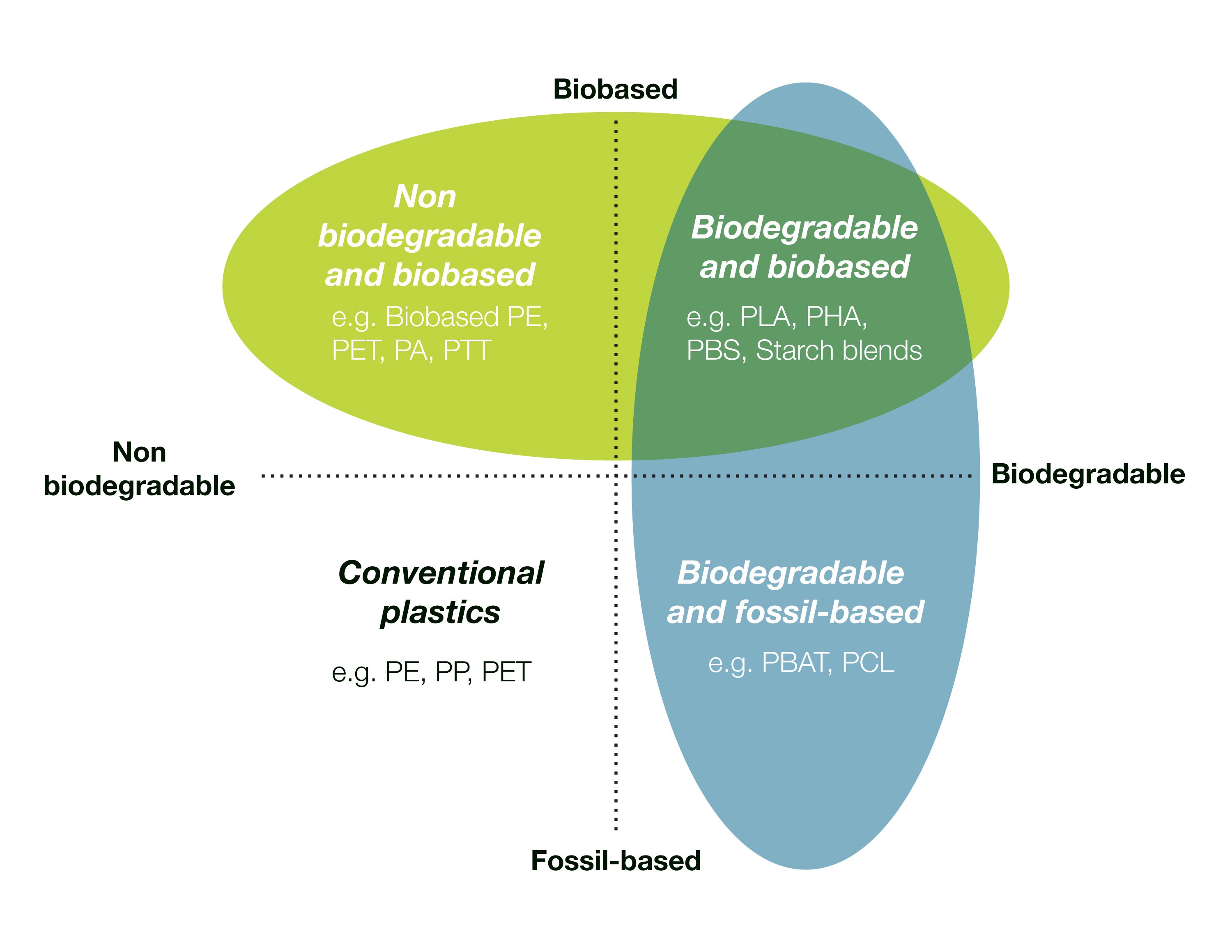

A clear distinction needs to be made in these plastic types:

If a plastic, or a component of a plastic, is made from a natural or renewable resource, it may be referred to as a "bio-based plastic". Hence polyethylene made from plant-based ethylene, or polyester (PET) which incorporates plant-based butane diol, can be called biopolymers - or bio- based polymers. However they are not biodegradable polymers.

The definition of "biodegradable/compostable plastic" is based on how the plastic behaves at the end of its life. Specifically, does it degrade quickly (depolymerize) in a commercial composting operation. There are several commercially available polycaprolactone (PCL)-based blends which do indeed meet this requirement.

To avoid ambiguity Plastics NZ is keen to avoid the use of the term 'biopolymer' or 'bioplastic' except where absolutely correct. Ideally these generic terms should be substituted by the more accurate and informative equivalents shown below.

To try and explain, we have listed the most commonly used polymers that are often termed "bioplastic":

- Biobased/renewable and non-biodegradable plastic

- Biobases/renewable and biodegradable plastic

- Fossil-baseed and biodegradable plastic

1. Bio-based/Renewable and Non-Biodegradable

These are polymers made fully, or partly, from natural and renewable resources -biomass*.

These types of non-biodegradable, bio-based plastics are manufactured in essentially the same way as conventional fossil-based plastics, but use biomass instead of fossil fuels as their building blocks. For example Ecostore polyethylene uses 100% ethylene monomer derived from biomass, certain nylons are 100% based on building blocks derived from castor oil, and Coca Cola's Plant Bottle is PET which is made from 30% biomass.

These plastics are not biodegradable. They are designed to be identical to conventional plastics. They can be fully recycled with conventional plastics where recycling is available.

2. Bio-based/Renewable and Biodegradable

These are plastics that are made fully, or partly, from biomass*. Most of these plastics are designed to be composted in an industrial composting facility and are biodegradable. Some are also able to be composted in home compost systems. The type of compost system the plastic is suited to should always be clearly identified for consumers using international standards and approved labelling.

Although these polymers (PLA, PBS PHA) belong to the 'polyester' family of polymers, and can be recycled, they cannot be recycled with conventional polyesters such as PET. In some cases they can have a negative effect on existing plastics recycling processes. They are based on building blocks which are susceptible to hydrolysis.

* Biomass is material of biological original (excluding material embedded in geological formations and material transformed to fossilised material). This includes organic material, e.g. trees, crops, grasses, tree litter, algae and waste of biological origin, e.g. manure.

3. Fossil-based and Biodegradable

Surprisingly, there are some plastics that are made from fossil-based resources that can biodegrade and be composted. This kind of plastic is not common. Commercial examples such as polybutylene adipate terephthalate (PBAT), and polycaprolactone (PCL) are available.

Conventional Plastics with Additives

To add to the confusion, there has been recent growth in traditional fossil-based plastics that use additives to make them degrade faster than normal.

For example, oxo-degradable additives that are incorporated at the point of manufacture at varying levels. These oxo-degradable additives are designed to break down the polymer chain - i.e. fragments the plastic into smaller pieces.

Plastics with these additives are often described as "degradable". They are fossil-based and are not compostable. They break down slowly (2-5 years) only when exposed to heat, sunlight, and air. Caution must be used when making claims about the degradability of plastics with such additives. A number of successful prosecutions have been taken by governments in the USA, New Zealand and elsewhere in the world, against companies making misleading claims about the effectiveness of degradable

additives.

Plastics Recycling

It is important to note that most fossil-based plastics are fully recyclable. The only limitation to the extent of plastics recycling is the availability of local recycling infrastructure.

Summary

There are many new types of plastics that are being termed bioplastics. However, there are important distinctions that must be made between how these new plastics behave, and how they can be dealt with at the end of their life. There are more specific and accurate terms that should be used.

Manufacturers and brand owners must exercise caution when marketing these new materials to consumers. Misleading or confusing claims about plastic types risks alienating consumers.

Increasingly, consumer watchdogs and regulatory authorities such as the New Zealand Commerce Commission are scrutinising material claims. Already, two companies in New Zealand have been prosecuted for misleading claims about the degradability of their plastics.

If you would like further information, or to discuss material selection, please contact Plastics New Zealand.